Efficient Manufacturing execution management solution

- Costs management on each product, each production stage

- Real-time production progress management

- Production scheduling

- Visualised reports on: progress, productivity, material consumption, and production costs

Similar products from Manufacturing Execution System MES-X

Master data settings aligned with customer’s business specifications

Allow manufacturers to define and set up master data according to their production specifications

- Define user

- Manage user access, ensuring data security

- Define product group & type

- Define product unit

- Define product

- Define sales order (SO), purchase order (PO)

- Define BOM, production stage, line/work station, efficiency

- Generate work schedule

- Define manufacturing order (MO)

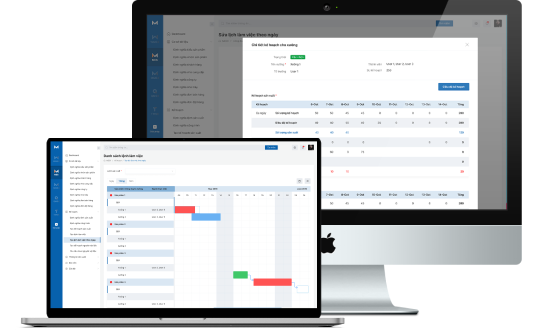

Production planning even without ERP

- Automatically generate production plan according to manufacturing orders

- Automatically generate work orders for each production stage

- Visualize detailed plan

- Enable manual & automated production scheduling

- Automate inventory tracking

- Forecast additional production/import quantity

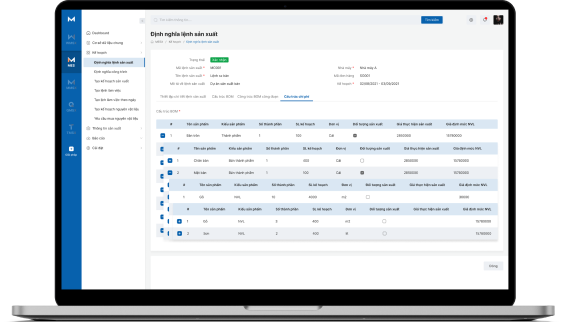

Define Manufacturing orders (MO) – Inventory tracking

- Automatically generate materials plan according to production plan & inventory (integrated with WMS-X)

- Automatically generate materials purchase requisition and PO according to production plan & material purchase forecast

Real-time progress update and management

- Update input

- Update stage progress

- Update error status

- Update production scrap

Fast stage transition

- Update the number of export/import stages

- Provide a list of step input commands

- Detailed statistics of the order to enter the stage

* QC before stage transition if QC is required

Transparent transition history tracking

- Provide production transaction history list

- Provide transaction history details

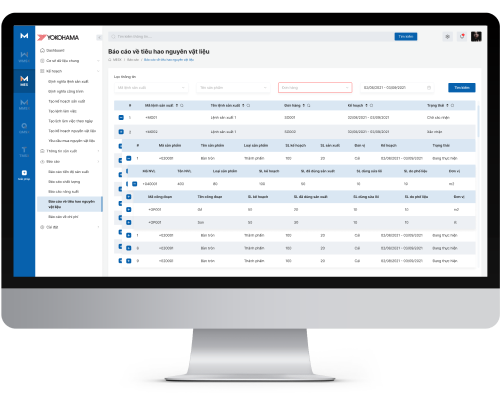

Visualized reports

- Visualized chart reports by

- Manufacturing order

- Finished product

- Semi-finished product

- Stage in progress

- Reports on overall progress by

- Stage

- Product

- Manufacturing order (MO)

- Reports on detailed daily progress for each workshop by

- Planned quantity

- Scheduling quantity

- Actual produced quantity

- Delayed quantity

- Planned quantity (Accumulated)

- Progress (Accumulated)

- Delayed quantity (Accumulated)

- Productivity report

- Planned/Actual production time cycle for 01 product

- Planned/actual productivity

- Planned/actual OEE each day, and accumulated to the current day

- Productivity comparison among workshops/lines by

- Efficiency

- OEE

- Reports on materials consumption by

- Quantity used in production

- Quantity used for error control

- Quantity due to production scrap

- Reports on estimated production costs, materials cost for 01 product/01 work order

- Reports on production costs, actual/estimated materials quantity for each product/MO

Flexible deployment On-premise & On Cloud

Diversity – Efficiency

On-Premise

- Deployed on customer’s server

- One-time purchase

- Self-maintenance according to company policy

- Maintenance fees required, complicated upgrading process

- An operation team required

- Costly IT infrastructure set-up

On Cloud

- Deployed on VTI’s server

- Recurring charges (affordable initial investment)

- Continuously and regularly operational support by the supplier

- No maintenance, system upgrade fees required (automatically upgraded functionality)

- No operation team required

- No cost for IT infrastructure set-up required

- No exit barrier (service can be stopped flexibly if required)

Our Customers

Digital transformation of manufacturing processes, leading the market 4.0 with MES-X

VietNam

VietNam 日本語

日本語